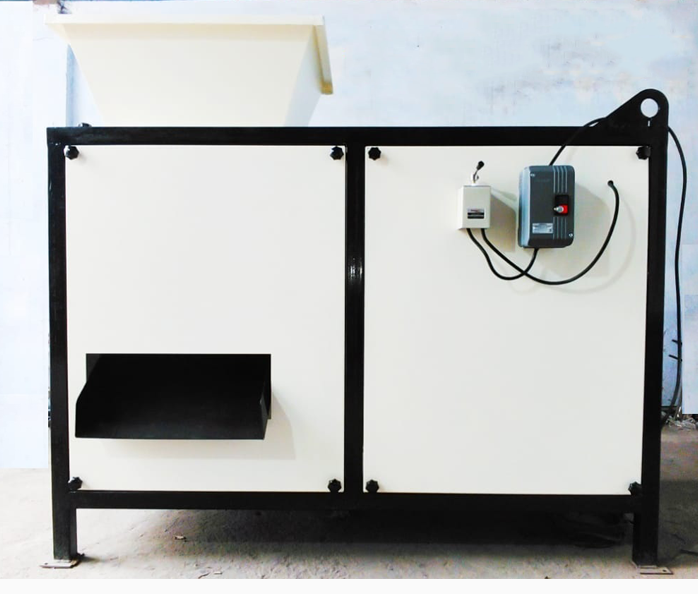

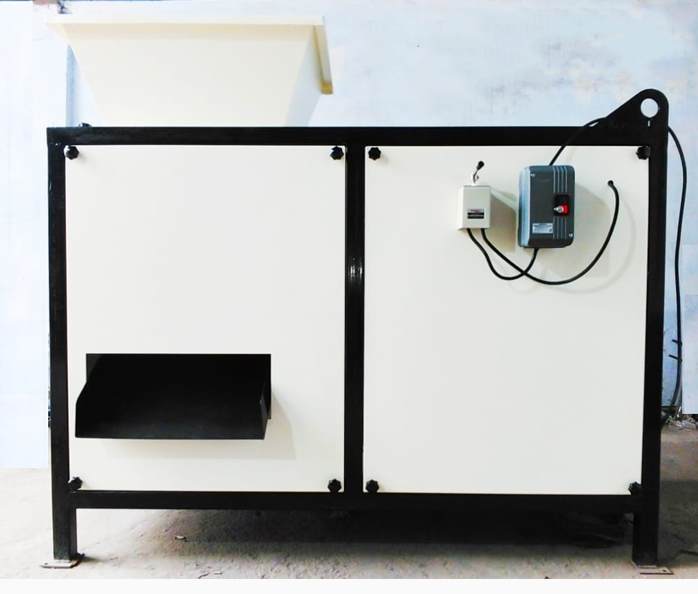

Twin-Shaft Shredder Machine

Twin Shaft Shredder – The Ultimate Waste Management Solution

At EnvCure, we are strong proponents of recycling and reusing industrial waste. We firmly believe that these materials, if properly managed, can be significantly valuable. One of the techniques to achieve this shredding them into manageable chunks. As a result, Team EnvCure has developed bespoke shredding machines that find applications depending on the industry’s requirements. Whether you're dealing with municipal solid waste or heavy industrial waste, our double shaft shredder is built to meet your specific shredding needs.| Product Code | Shredding Chamber | Gear Box | Motor | Input Hopper |

|---|---|---|---|---|

| ECS 20 | 250 mm X 200 mm | Worm Type | 2 HP | 550 mm X 500 mm |

| ECS 30 | 300 mm X 250 mm | Worm Type | 3 HP | 600 mm X 550 mm |

| ECS 50 | 350 mm X 350 mm | Worm Type | 5 HP | 650 mm X 650 mm |

| ECS 50-1 | 350 mm X 350 mm | Helical Type | 5 HP | 650 mm X 650 mm |

| ECS 75 | 400 mm X 350 mm | Helical Type | 7.5 HP | 700 mm X 650 mm |

| ECS 75-1 | 400 mm X 400 mm | Planetary Type | 7.5 HP | 700 mm X 700 mm |

| ECS 100 | 500 mm X 400 mm | Planetary Type | 10 HP | 800 mm X 700 mm |

| ECS 502 | 450 mm X 400 mm | Planetary Type ; 02 Nos | 5 HP ; 02 Nos | 750 mm X 700 mm |

| ECS 752 | 500 mm X 400 mm | Planetary Type ; 02 Nos | 7.5 HP ; 02 Nos | 800 mm X 700 mm |

| ECS 1002 | 600 mm X 400 mm | Planetary Type ; 02 Nos | 10 HP ; 02 Nos | 900 mm X 700 mm |

| ECS 1502 | 700 mm X 600 mm | Planetary Type ; 02 Nos | 15 HP ; 02 Nos | 1000 mm X 900 mm |

| ECS 2502 | 850 mm X 600 mm | Planetary Type ; 02 Nos | 25 HP ; 02 Nos | 1150 mm X 900 mm |

| ECS 4002 | 1000 mm X 800 mm | Planetary Type ; 02 Nos | 40 HP ; 02 Nos | 1300 mm X 1100 mm |

Key Features of Our Dual Shaft Shredder

-

This machine utilizes two sharp, steel blades to shred waste materials, leading to reduced time of waste management.

This machine utilizes two sharp, steel blades to shred waste materials, leading to reduced time of waste management.

-

Owing to two blades managing waste materials simultaneously, it does not require the perforated method.

Owing to two blades managing waste materials simultaneously, it does not require the perforated method.

-

This variant is suitable for medium to heavy-duty waste management. It is capable of handling heavier materials such as tyres, tin boxes, metal waste, to name a few.

This variant is suitable for medium to heavy-duty waste management. It is capable of handling heavier materials such as tyres, tin boxes, metal waste, to name a few.

-

Number of variants are available in accordance with different parameters such as Motor, Gear Box , Blade Material to name a few. If you’re an industry looking to better manage your waste materials and passionate about recycling and reusing them, we can help you!

Number of variants are available in accordance with different parameters such as Motor, Gear Box , Blade Material to name a few. If you’re an industry looking to better manage your waste materials and passionate about recycling and reusing them, we can help you!

Benefits of Our Twin Shaft Shredder

-

Improved Waste Management

By shredding materials into smaller pieces reduces waste volume, you can make recycling and disposal more efficient.

-

Enhanced Recycling Efficiency

As shredded materials are easier to process, it helps in creating a more sustainable waste management system.

-

Cost-Effective Solution

With reduced operational time and minimal maintenance, this shredder offers a budget-friendly solution for industries managing large volumes of waste.

-

Environmental Impact

By supporting recycling and waste reuse, the shredder helps reduce landfill waste, contributing to environmental sustainability.

Specifications of Our Dual Shaft Shedder

-

Shredding Chamber Size: The machine shredding chamber size ranges from 250 mm x 200 mm to 1000 mm x 800 mm.

Shredding Chamber Size: The machine shredding chamber size ranges from 250 mm x 200 mm to 1000 mm x 800 mm.

-

Motor Capacity: Get options from 2 HP to 40 HP for various waste volumes.

Motor Capacity: Get options from 2 HP to 40 HP for various waste volumes.

-

Gearbox Type: Choose the gearbox type from worm, helical, and planetary types for smooth operation.

Gearbox Type: Choose the gearbox type from worm, helical, and planetary types for smooth operation.

-

Input Hopper Size: Enjoy multiple options ranging from 550 mm x 500 mm to 1300 mm x 1100 mm.

Input Hopper Size: Enjoy multiple options ranging from 550 mm x 500 mm to 1300 mm x 1100 mm.

Applications of Industrial Shredder Machine

-

Municipal Solid Waste

Shred urban waste like plastic bottles, paper, and organic waste so that you can recycle it easily.

-

Tyre Recycling

Break down old tires into smaller pieces for safe disposal and recycling.

-

Metal Waste Processing

Efficiently shreds metal scrap, such as tin boxes and steel scrap.

-

Plastic Recycling

Shreds plastic waste to reuse it in new products.

-

E-Waste Management

Shreds electronic waste like computers and phones so that you can facilitate the recovery of valuable materials and safe disposal of harmful components.

-

Agricultural Waste

Processes plant debris and food scraps so that you can handle and recycle them easily.

FAQs Dual Shaft Shredder

These terms are often used interchangeably. Both feature two rotating shafts for efficient shredding, with no significant difference in design or functionality.

It uses rotating blades to shred mixed waste, such as plastics, paper, and organic materials, into smaller pieces for easier sorting and recycling.

Industries including waste management, recycling, automotive, electronics, and manufacturing rely on industrial shredders to process large volumes of waste, from metals and plastics to tyres and e-waste. EnvCure’s Twin Shaft Shredder is the go-to choice for efficient waste reduction and recycling in a wide range of industries.